realmsenterprises@gmail.com +91-7021220544, +91-7666776059

- Send SMS Send Email

| Business Type | Supplier, Trader, Importer |

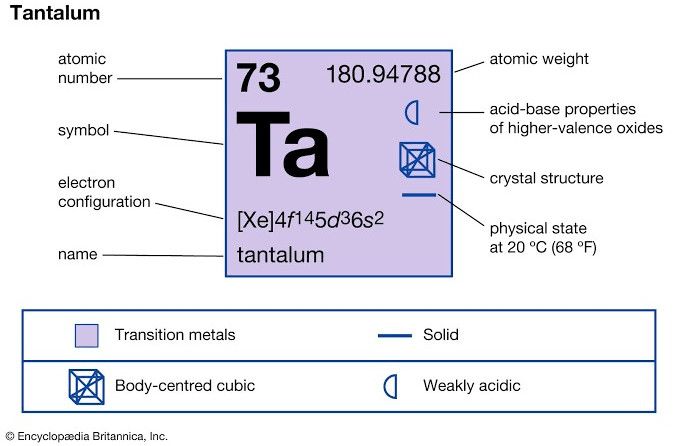

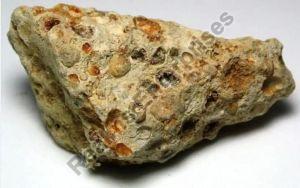

| Type | Tantalite Ore |

| Packaging Type | Loose |

| Application | Industrial |

| Click to view more | |

Product Details

Tantalum (Ta) is a technology-critical metal, which has important applications in many strategic emerging industries, such as electronic, and aerospace, and there are no substitute materials for Ta so far. The supply crisis of Ta has kept growing globally over the past two decades. This work presents a comprehensive review of tantalum resources and its production. There is less than 300 kt Ta in the earth's crust, and the production of primary Ta is an energy- and materials-demanding process. Ta can also be recovered from tin smelting slag, lithium ores, end-of-life tantalum products, etc., and they can account for 37% of the total Ta production. The HF leaching−solvent extraction−sodium potassium fluorotantalate reduction process is the most widely used technology in producing Ta. However, long process and environmental issues have limited the sustainable development of this method. Clean production technologies and efficient recycling of Ta should receive continuous attention.

The invention relates to a preparation method of a chemical mechanical tantalum polishing solution. The preparation method is characterized by comprising the following steps of: cleaning a container and a pipeline, cleaning a reactor, a pipeline and devices 3 times by adopting ultra-pure deionized water of 18 megohms; carrying out ultra-clean treatment on worker bodies, gloves, masks and clothes; diluting an alkaline pH regulator with ultra-pure deionized water of 18 megohms, gradually adding to the polishing solution in the reactor and stirring gases by adopting a negative pressure vortex method, wherein the alkaline pH regulator is added until the polishing solution reaches a pH value of 9-12; and gradually adding an FA/OI surface active agent to the polishing solution in a negative pressure vortex state in the reactor, gradually adding nano silica sol with the grain size of 15-100nm and the concentration of 40-50 percent by weight to the polishing solution in the reactor so that the polishing solution can keep the vortex state under negative pressure while gases are stirred until the tantalum polishing solution of an aqueous solution of SiO2 is prepared. The invention has the advantages that the selected alkaline polishing solution does not corrode the equipment, the silica sol has good stability, and the defects of heavy pollution, easy gelling, and the like of the acidic polishing solution are solved.

Looking for "Tantalite Ore" ?

Explore More Products